Balancing Priorities?

by Paul Hyett, PPRIBA, Hon FAIA

Vickery Hyett Architects, Founder—Partner

July 19, 2023

Paul Hyett contrasts public safety in two remarkable industries.

Flying High?

When its front wheels first lifted off the ground, Concorde’s engines had already consumed more oxygen during its acceleration down the runway than the entire Swiss nation breathes in a year.

Weighing a mere 70 tons empty, the craft would carry just 10 tons of people and luggage because its fuel load was a whopping 90 tons – some 113% more than the aggregate weight of the plane, passengers and luggage. Seen in this light, Concorde was little more than a highly engineered, beautiful, flying gas can1.

Figure 1

During takeoff and throughout flight, computer programmes would constantly redistribute the unburned kerosene to keep the plane “trim.” Simultaneously, the remaining fuel was used as a coolant for the engine and generator, as well as for the hydraulic and air conditioning equipment. Seen in its entirety, the plane was conceived as a system and its design was incredibly sophisticated: At supersonic speed, parts of its external skin reached 127 degrees centigrade, and the fuselage expanded by up to 250 mm in length. Designing a “carriage” that would maintain life-support and comfort in such harsh, volatile conditions at altitudes of up to 60,000 feet and speeds of Mach 2, or 1350 mph, was a tremendous feat.

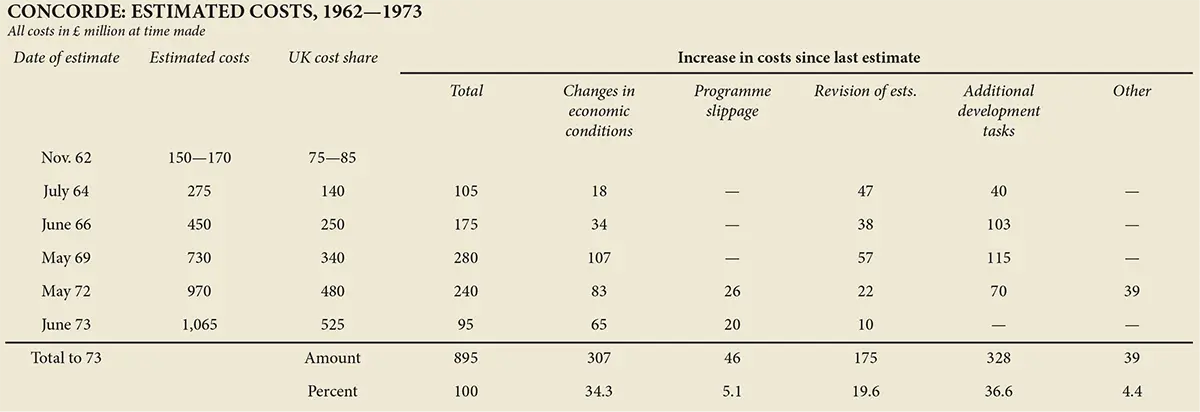

But the numbers in Figure 1 reveal an altogether dismal story: Only 20 Concordes would be built against the 250 sales required to cover the project’s development costs and the 450 the manufacturer had expected to produce!

In preparation for the production run, four prototypes had been made and exhaustively tested (model numbers, 001, 002, 101 and 102). Subsequently, two preproduction models (201 and 202) were assembled for further development testing and design refinement.

Of the 20 produced, 10 Concordes were built in Britain and 10 in France. Prototype 001 was constructed at Toulouse, where, on 11 December 1967, it was wheeled out of its hangar for the first public showing in the presence of the then British Minister for Technology, Anthony Wedgwood Benn2. Finally, on 2 March 1969, after extensive ground trials, Concorde took to the skies under the captaincy of Andre Turcat, chief test pilot for Aérospatiale of France.

Figure 2: Source: Peter Hall, “Great Planning Disasters,” page 96.

Technological vs. Financial Factors

Around that time, as a junior air force cadet, I flew over Filton airfield in a two-seater de Havilland Chipmunk training plane. Far below, where the British prototype was being built, I saw her undergoing ground trials along the runways. Prototype 002 would first fly on 9 April 1969 with Brian Tubshaw, chief test pilot for the British Aircraft Corporation, at the controls.

The ongoing testing processes were painstakingly slow, and it would not be until some six months later that the French prototype would first break the sound barrier on 1 October 1969.

In technical terms the project was a great success: Supersonic flight was made available to the public for the first time, with the 14 production planes (nos. 203 to 216) completing 83,301 service flights between them, with a total flying time of 248,847 flying hours. In all, this constituted some 233 million miles of flight, during which over one million bottles of champagne were consumed.

But despite these successes, the project was a financial disaster: Between 1975 and 1979 only the state airlines of France and Britain – no doubt under duress – would purchase Concordes, and then just seven each. Thereafter production ceased3.

Incredibly, and long before the first production planes even entered service in early 1975, disastrous sales results had already indicated that the project was doomed to financial failure. Figure 2 captures the scale of the budgeting errors.

In short, costs escalated sevenfold during development and ultimately resulted in a twenty-eightfold increase. Under any rational review, the project should have been cancelled multiple times. Instead, the aspiration to get this extraordinary plane safely into the air became a sole priority, which overwhelmed any obligation to respond to commercial trends and market intelligence4.

Because they had failed to balance their priorities, no one had had the wherewithal to soberly assess the inevitable commercial catastrophe that was in the making and “pull the plug” on the project. Consequently, the respective French and British governments collectively footed a bill of £4 billion for just seven aircraft a piece – a monstrous £14.68 billion or US$ 18.28 billion in today’s currency.

Safety at the Fore?

Throughout all this, and notwithstanding the tragic loss of Air France Concorde 203 on 25 July 2000, the matter of safety remained at the fore of the entire endeavour, as it continues to do for all commercial aircraft design, construction, operation and maintenance.

Sadly, this has not been the case within the British construction industry, as has been brought into sharp focus by the horrific fire at Grenfell Tower in London on 14 June 2017, causing the deaths of 72 residents. Commercial priorities – speed of construction, “just in time” production information, poorly trained workforces, an irresponsible instinct for downstream risk transfer and inadequate checking regimes – had each been progressively promoted to a point where they ultimately took precedence over safety in design, product selection and construction. This sad situation was only exacerbated by the introduction, over decades, of a multitude of new materials and construction systems that had not been adequately tested. Against all this, building codes had not been sufficiently updated, and the authority of the state building control system had been gradually and relentlessly undermined.

In the immediate aftermath of the Grenfell fire, the British government instructed Dame Judith Hackitt to conduct a review of the building regulations for fire safety, and she found them deeply flawed and “not fit for purpose.” Her report was published in May 2018. Paul Morrell and Anneliese Day KC were subsequently instructed to conduct a similar review of products used in construction, particularly focused on their testing and certification. Their findings and criticisms, published in April 2023, were again damning.

We now await the report of Sir Martin Moore-Bick, who was appointed by the government to lead an inquiry into the fire, but it is already clear from the Hackitt and Morrell reports that, for a long time, all has been far from well within the U.K. construction industry.

Tracing the Demise

I would trace the demise back to the 1984 Building Act, which introduced the 1985 Building Regulations. It was at this point that U.K. construction moved from a largely “prescriptive system” (as still operates in the U.S.) to a “functional system.” The reason for this shift was allegedly to encourage innovation in construction methods.

Unfortunately, and however well-intentioned the switch to a functional system, the reality has been that the essential purpose of building regulations – public and user safety – was undermined as product manufacturers, subcontractors and suppliers increasingly sought to game the system by exploiting ambiguities in the government’s (nonstatutory) guidance on compliance, testing protocols and the certificates under which products and components were marketed and sold.

In parallel with these changes, Design -Build emerged as a project procurement vehicle and delivery system. Contractors competing for business in an ever-harsher market were thus able to gain substantial control of the product selection and specification roles that had hitherto been the preserve of architects and specialist consultants.

The third major change came about through the introduction of new construction techniques and technologies. High-rise construction had long been a driver towards progressively lighter materials and systems, especially in external walls, where an ever “thinner” construction was also in demand in pursuit of maximum lettable areas. But, from the 1980s onwards, the eco-agenda intensified the requirements for high performing insulation products – maximum “U” values against minimum thickness. This led to the extensive introduction of polymerics into external wall construction, even in buildings over 18 metres in height, despite being contrary to the advice of the government’s guidance as given in “Approved Document B2.”

Because priorities had gotten out of kilter, the U.K. construction industry has now found itself with a massive, unanticipated, overriding priority: the regaining of trust.

In sharp contrast, over the same period, the airline industry has never lost sight of the fact that its very existence depends on trust and, in consequence, has never allowed anything to take priority over safety.

Balancing priorities should forever remain a lesson to us all.

Paul Hyett is the founder of Vickery Hyett Architects, past president of the RIBA and a regular contributor to DesignIntelligence.

FOOTNOTES:

1 By way of comparison, a Boeing 747 – of which 1,574 were built – carries 106 tons of fuel, which is 45% of its combined weight and payload.

2 For a later, related, brilliant speech by Tony Wedgewood Benn on ethics and wartime bombing, see https://youtu.be/HfXmpJRZPYI.

3 For more on Concorde, see https://www.heritageconcorde.com/airframe-detail.

4 By way of contrast, on 5 October 1930, the British Airship R101 had been launched ahead of clearing all testing on its maiden trip to India. It crashed at a mere 13 mph in France with the loss 48 of the 54 people on board, ending further British development of airships. Its R102 sister ship was also scrapped.